|

For coarse to fine

dry & wet grinding of all types of chemicals, coal, colours,

cosmetics, dyes, food colours, fertilizers, gum, gram flours,

manures, minerals, medicine herbs, pharmaceuticals, plastics,

paints, pigments, pesticides, sugar, spices, salt, tobacco, tea

pre-mixes etc.

PRINCIPLE OF PULVERISING :

Shubh Micro Pulverizer is compact, low cost, highly efficient

grinding mill, capable of grinding variety of products from coarse

to fine mesh size. Material to be pulverized is crushed

between high speed moving beaters & serrated liner & by

impact between rapidly moving beaters & the particle itself,

the energy of the rapidly moving beaters dissipating itself into

the particles being ground by virtue of their inertia, thus

causing the particles size reduction.

|

The Basic

Components |

|

The

material to be pulverized can be fed to grinding chamber

in different ways |

|

|

|

| SCREW

FEEDING |

GRAVITY

FEEDING |

PADDLE

TYPE FEEDING |

|

Screw

Feeding - Powered by electric motor the

material to be ground is fed to the grinding chambers

in a uniform way by screw feeders. Feed

screws are made in single & multiple types designed

to convey the material from feed hopper to

grinding chamber & at the same time act as a

pre-crusher for reducing large soft mass of

material to suitable size for the micro

pulverizers. Screw feeding can be provided

with variable speed arrangement. |

Gravity

Feeding - This arrangement is extremely

successful for materials like medicine herbs,

spices, spices, heena leaves etc. Which

cannot be conveyed in to the grinding chamber due

to their light weight or material which are highly

hydroscopic. Gravity feeding can also be

used to pulverize materials like sugar, salt or

carbon as these types of material are extremely

easy to grind & does not require screw

feeding. Gravity feeding arrangement

consists of a specially designed hopper with

sliding valve, which conveys the material

into the grinding chamber by gravity. |

Paddle

Type Feeding - This arrangement is suitable

for grinding of over size materials which cannot

be conveyed into the grinding chamber due to

their size. This type feeding arrangement

consists of a specially designed paddle in the

hopper with bearings which precrushes before

conveying the material into the grinding

chamber. |

| SIDE

FEEDING |

BEATERS |

LINER |

|

Side

Feeding - This arrangement is suitable for

extremely light weight material. This type

of feeding arrangement consists of a specially

designed gravity hopper at the side of the mount

which conveys the material into grinding chamber

by suction. |

Beaters

- This are set of beaters revolving at high

velocity in the chamber & beat in the

materials as it enters from the screw

feeders. These hammers are forged out of

hardened material. Shubh micro also offers

serrated type beaters for heat sensitive

materials. |

Liner

- High speed revolving beaters pulverize the

material against the rachet teeth liner into fine

powder of desired mesh. The pulverized fine

powder is pushed through the screen into the

collecting bag by the air draft generated due to

the centrifugal movement of the beaters. |

|

|

|

|

|

SCREEN /

SIEVE

SCREEN - The required coarse to fine mesh size of

material is obtained by different types of screen.

The particle size is not accomplished by the

screens. They hold the material in the chamber until

the particle is pulverized to the required size by the

hammers and the liner.

CLEANING

CLEANING - is very easy as the interior of the

grinding chamber is smoothly finished. It is

possible to dismantle each part of the unit for easy &

through cleaning & reassembling with the use of simple

tools in no time. |

|

ADVANTAGES OF

SHUBH MICRO PULVERIZER

Capable

of wet grinding

Consumes very less space |

Easy

to clean,

Dust proof operation |

Low

maintenance

Low Power |

|

|

| Model |

Main

Drive

HP |

Feed

Drive

HP |

Top

Rotor Speed

R.P.M. |

Upto

300 mesh

Kgs./Hr. |

| MINI |

1 |

- |

9,600 |

10-15 |

| BABY |

2 |

0.5 |

9,600 |

15-20 |

| MP-1 |

5 |

0.5 |

8,400 |

40-60 |

| MP-2 |

10-15 |

1 |

6,900 |

200-300 |

| MP-3 |

20-30 |

1.5/- |

4,600 |

500-700 |

| MP-5 |

50-60 |

- |

3,450 |

1500-1800 |

Output capacity will

vary, depending upon physical properties of material.

|

|

|

| MINI

GMP |

MP-3

S.S. Contact Parts |

Baby

S.S. Contact Parts |

|

|

|

| MP-1

GMP |

MP-5

M.S. |

MP-2

M.S. |

| All

the above models are available in MOC-C.I/M.S./Contact

Parts In S.S. & GMP Models. |

|

ARRANGEMENT FOR

GRINDING LIQUIDS & SLURRIES

For recirculation or multi passing of liquids &

slurries an arrangement of this type is recommended. The

circulating pump at the discharge of the lower hopper carries

the material back to the feed of the Shubh Micro Pulverizer

for repassing through the mill. When the grinding is

finished the material is discharged into the drum or pumped to

wherever desired.

|

|

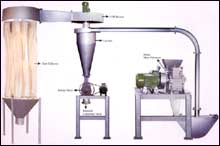

SHUBH MICRO

PULVERIZER WITH PNEUMATIC SYSTEM

Flexible design enables alteration of the system as per

space available.

Advantages

1) Total Dust Free Environment

2) Increase in Output Capacity

3) Labour Savings

4) Guaranteed Performance

5) Compact & Highly Efficient

6) Uniform Production. |

|

|